1) Electroforming stencil

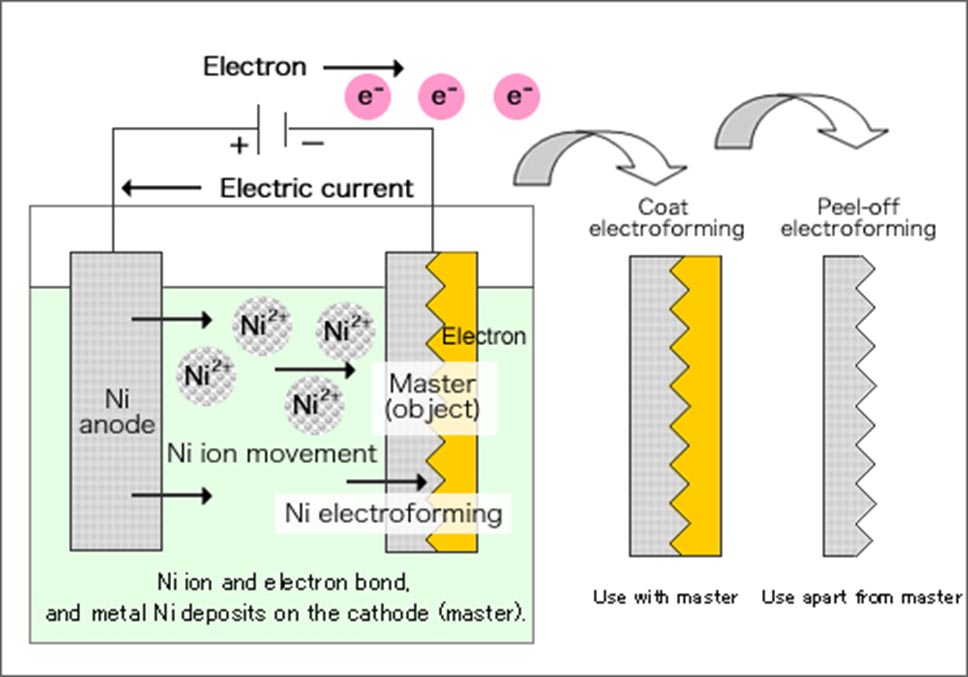

The masana'antu manufa na electroformed stencil: da electroformed samfuri da aka yi ta hanyar buga photoresist abu a kan conductive karfe tushe farantin, sa'an nan ta hanyar masking mold da ultraviolet daukan hotuna, sa'an nan da bakin ciki samfuri ne electroformed a cikin electroforming ruwa.A haƙiƙa, electroforming yana kama da electroplating, sai dai cewa takardar nickel bayan electroforming ana iya cire shi daga farantin ƙasa don samar da stencil.

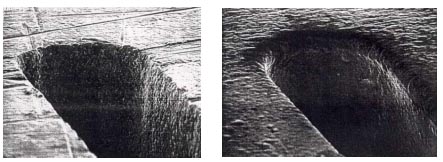

Electroforming stencil yana da halaye masu zuwa: babu damuwa a cikin takardar ƙarfe, bangon rami yana da santsi sosai, stencil na iya zama kowane kauri (a cikin 0.2mm, sarrafa lokacin lokacin lantarki), rashin amfani shine farashin yana da yawa.Hoton da ke gaba shine kwatancen ragar karfe na Laser da bangon ragar karfe na lantarki.Ganuwar rami mai santsi na ragar ƙarfe na ƙarfe na lantarki yana da sakamako mafi kyau bayan bugu, ta yadda rabon buɗewa zai iya zama ƙasa da 0.5.

2) Tsani stencil

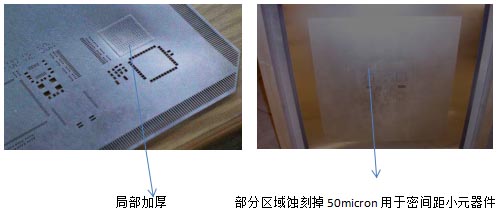

Ragon karfen da aka tako na iya zama mai kauri ko bakin ciki.Ana amfani da sashin da aka yi kauri ne don buga fakitin siyar da ke buƙatar manna mai yawa, kuma ɓangaren mai kauri yana samuwa ta hanyar lantarki, kuma farashin ya fi girma.Ana samun thinning ta hanyar sinadarai etching.Ana amfani da ɓangaren bakin ciki don buga pads na ƙananan abubuwan da aka rage, wanda ke sa tasirin rushewa ya fi kyau.Ana ba da shawarar masu amfani waɗanda suka fi dacewa da tsada don amfani da etching sinadarai, wanda ya fi arha.

3) Nano Ultra Coating

Rufewa ko sanya wani Layer na Nano-shafi a saman raga na karfe, nano-coating yana sa bangon rami ya kori man sikelin, don haka tasirin rushewa ya fi kyau, kuma ƙarfin juzu'i na bugu na ƙwanƙwasa ya fi daidaituwa.Ta wannan hanyar, ingancin bugu yana da garanti, kuma ana iya rage adadin tsaftacewa da gogewar ragamar ƙarfe.A halin yanzu, yawancin matakai na gida suna amfani da Layer na Nano-coating, kuma sakamakon ya raunana bayan wani adadin bugu.Akwai nano-coatings kai tsaye plated a kan ragar karfe, wanda ke da tasiri mafi kyau da dorewa, kuma ba shakka farashin ya fi girma.

3. Biyu solder manna gyare-gyaren tsari.

1) Buga/Bugawa

Ana amfani da injunan bugu guda biyu don bugawa da kuma samar da manna solder.Na farko yana amfani da stencil na yau da kullun don buga pads na ƙananan kayan aiki tare da farati mai kyau, na biyu kuma yana amfani da stencil na 3D ko stencil don buga pads na manyan abubuwan.

Wannan hanya tana buƙatar na'urorin bugawa guda biyu, kuma farashin stencil shima yana da yawa.Idan ana amfani da stencil na 3D, ana buƙatar tsefewar tsefe, wanda ke ƙara farashin kuma ingancin samarwa shima ƙasa ne.

2) Buga / fesa tin

Na farko solder manna printer yana buga ƙananan kayan aikin da ke kusa, sannan na'urar tawada ta biyu tana buga manyan fakitin abubuwa.Ta wannan hanyar, tasirin gyare-gyaren gyare-gyare na solder yana da kyau, amma farashin yana da girma kuma ingancin yana da ƙasa (dangane da adadin manyan pads).

Masu amfani za su iya zaɓar yin amfani da abubuwan da ke sama da yawa mafita gwargwadon halin da suke ciki.Dangane da farashi da ingancin samarwa, rage kauri na stencil, ta yin amfani da ƙananan buƙatun buƙatun buƙatun buƙatun yanki, da matakan stencil sun fi dacewa da zaɓi;masu amfani waɗanda ke da ƙarancin fitarwa, buƙatu masu inganci, da masu amfani marasa tsada za su iya zaɓar Shirin bugu / jet.

Lokacin aikawa: Agusta-07-2020