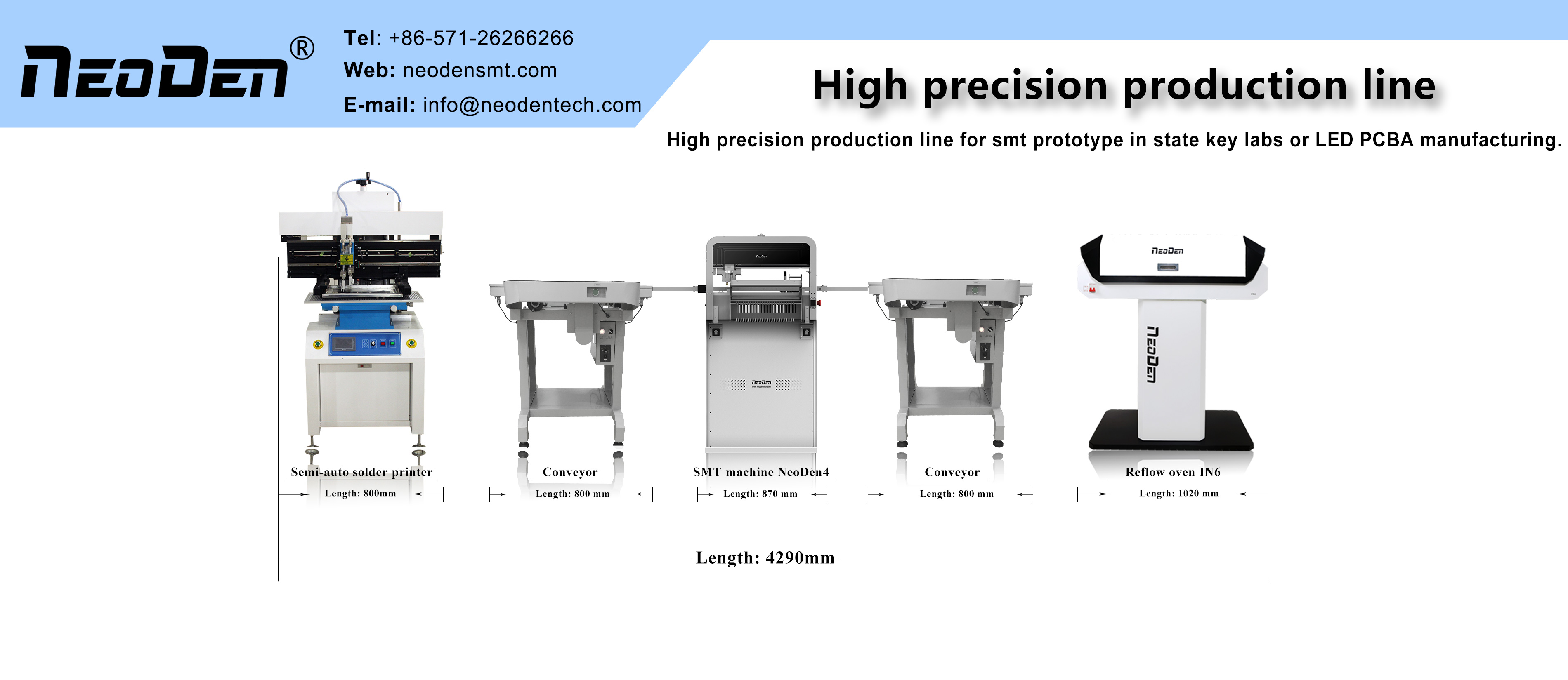

SMT PCB Soldering Machine

SMT PCB Soldering Machine

6 zones zane, haske da m.

Ƙarfafa fakitin katun mai nauyi, nauyi mai sauƙi kuma mai dacewa da muhalli.

NeoDen IN6 yana ba da ingantaccen siyarwar sake kwarara don masana'antun PCB.

Ƙirar tana aiwatar da farantin dumama na aluminum wanda ke ƙara yawan ƙarfin makamashi na tsarin.

Tsarin tace hayaki na ciki yana inganta aikin samfur kuma yana rage fitarwa mai cutarwa, shima.

Ƙayyadaddun bayanai

| Sunan samfur | SMT PCB Soldering Machine |

| Bukatar wutar lantarki | 110/220VAC 1-lokaci |

| Ƙarfin max. | 2KW |

| Yawan yankin dumama | Na sama3/ kasa3 |

| Gudun jigilar kaya | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 30mm ku |

| Kewayon sarrafa zafin jiki | Yanayin zafin jiki ~ 300 digiri celsius |

| Daidaitaccen sarrafa zafin jiki | ± 0.2 digiri Celsius |

| Rarraba yawan zafin jiki | ± 1 digiri Celsius |

| Faɗin siyarwa | 260 mm (10 inci) |

| Tsawon tsari dakin | 680 mm (26.8 inci) |

| Lokacin zafi | kusan25 min |

| Girma | 1020*507*350mm(L*W*H) |

| Girman tattarawa | 112*62*56cm |

| NW/GW | 49KG / 64kg (ba tare da tebur aiki ba) |

Daki-daki

Yankunan dumama

Zane 6, (3 saman|3 kasa)

Cikakken convection na iska mai zafi

Tsarin sarrafawa na hankali

Ana iya adana fayiloli masu aiki da yawa

Launi tabawa

Ajiye makamashi da yanayin yanayi

Gina-in solder tsarin tace hayaki

Ƙarfafa fakitin katun mai nauyi

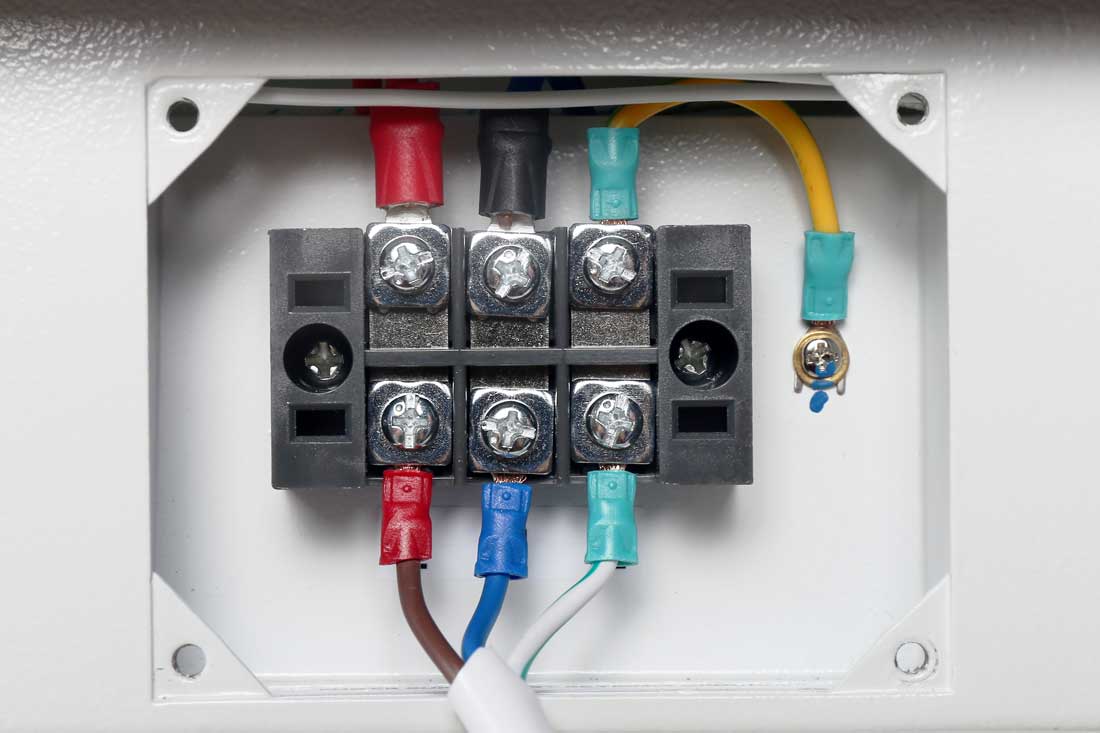

Haɗin Kayan Wutar Lantarki

Bukatar samar da wutar lantarki: 110V/220V

Nisantar masu ƙonewa da fashewa

Cikakken bayani game da saitin yankin zafin jiki

♦ Saita zafin jiki da saurin bel zuwa ƙimar farko, zuwa tanda mai sanyaya, ya kamata a preheated na minti 25.

♦Lokacin da yawan zafin jiki ya kasance barga, bari PCB ya wuce tsarin farfadowa na zafi.Idan babu sake kwarara, zai iya rage saurin jujjuya sarkar canja wuri yadda ya kamata.Wata hanya ita ce, kada ku daidaita saurin, kuma ƙara yawan zafin jiki yadda ya kamata.Lokacin daidaita zafin jiki, lura cewa ba zai iya wuce PCB da ƙarfin ɗaukar kayan aiki ba.

♦Bari PCB ya wuce tsarin sake gudana a cikin sabon saurin ko sabon yanayin zafin jiki.Idan babu sake kwarara, juya don sake yin matakin da ke sama.In ba haka ba, buƙatar juyar da yanayin zafi.

♦ Zazzabi zafin zafin jiki yana daidaitawa bisa ga PCB.Kuna iya daidaita saurin jujjuya sarkar canja wuri don daidaita zafin jiki.Rage saurin jujjuya sarkar canja wuri na iya ƙara yawan zafin samfurin.Akasin haka, zaku iya rage zafin samfurin zafi.

FAQ

Q1:Wadanne kayayyaki kuke siyarwa?

A: Kamfaninmu ya yi ciniki a cikin samfuran masu zuwa:

SMT kayan aiki

Na'urorin haɗi na SMT: Masu ciyarwa, sassa masu ciyarwa

SMT nozzles, injin tsabtace bututun ƙarfe, tace bututun ƙarfe

Q2: Menene game da lokacin jagora don samar da taro?

A: Gaskiya, ya dogara da adadin tsari da lokacin da kuka sanya oda.Koyaushe 15-30 kwanaki dangane da tsari na gaba ɗaya.

Q3:Mitoci nawa murabba'in masana'anta?

A: Fiye da murabba'in murabba'in 8,000.

Game da mu

Masana'anta

Mallakar cibiyar mashin ɗin kansa, ƙwararren mai tarawa, mai gwadawa da injiniyoyin QC, don tabbatar da ƙarfin ƙarfi don masana'antar injin NeoDen, inganci da bayarwa.

ƙwararrun ƙwararrun ƙwararrun ƙwararrun Ingilishi & injiniyoyin sabis, don tabbatar da saurin amsawa cikin sa'o'i 8, bayani yana bayarwa cikin awanni 24.

NeoDen yana ba da tallafin fasaha na tsawon rai da sabis don duk injunan NeoDen, haka kuma, sabunta software na yau da kullun dangane da amfani da gogewa da ainihin buƙatar yau da kullun daga masu amfani.

Takaddun shaida

nuni

Idan kuna buƙata, da fatan za ku iya tuntuɓar mu don ƙarin bayani.

Q1:Wadanne kayayyaki kuke siyarwa?

A: Kamfaninmu ya yi ciniki a cikin samfuran masu zuwa:

SMT kayan aiki

Na'urorin haɗi na SMT: Masu ciyarwa, sassa masu ciyarwa

SMT nozzles, injin tsabtace bututun ƙarfe, tace bututun ƙarfe

Q2:Yaushe zan iya samun ambaton?

A: Yawancin lokaci muna magana a cikin sa'o'i 8 bayan mun sami binciken ku.Idan kuna gaggawa don samun farashin, da fatan za a gaya mana don mu ɗauki fifikon bincikenku.

Q3:Zan iya ziyartar masana'anta?

A: Ko ta yaya, muna maraba da zuwanku, kafin ku tashi daga ƙasarku, don Allah ku sanar da mu.Za mu nuna muku hanya kuma za mu tsara lokaci don ɗaukar ku idan zai yiwu.