Yadda ake amfani da manna solder a tsarin PCBA?

(1) Hanya mai sauƙi don yin la'akari da danko na man naman alade: Ƙara man naman alade tare da spatula na kimanin minti 2-5, ɗauko ɗan lemun tsami tare da spatula, sa'an nan kuma bar man naman alade ya fadi a hankali.Danko yana da matsakaici;idan manna mai siyar bai zamewa ba kwata-kwata, dankowar man na’urar ya yi yawa;idan manna mai siyar ya ci gaba da zamewa da sauri, dankon mai siyar ya yi kankanta;

(2) Yanayin ajiya na manna mai siyarwa: sanyaya a cikin sigar da aka rufe a zafin jiki na 0 ° C zuwa 10 ° C, kuma lokacin ajiya gabaɗaya shine watanni 3 zuwa 6;

(3) Bayan an fitar da manna daga cikin firij, sai a dumama shi a zafin jiki na sama da awa 4 kafin a iya amfani da shi.Ba za a iya amfani da hanyar dumama don komawa zuwa zafin jiki ba;bayan manna solder ya dumama, ana buƙatar motsawa (kamar hadawa da na'ura, motsawa 1-2 Minutes, motsawa da hannu yana buƙatar motsawa fiye da minti 2) kafin amfani;

(4) A yanayi zafin jiki na solder manna bugu ya zama 22 ℃~28 ℃, da kuma zafi ya zama kasa 65%;

(5) Buga man solder 1. Lokacin bugu da manna solder, ana bada shawarar yin amfani da manna mai siyar tare da abun ciki na ƙarfe na 85% zuwa 92% da rayuwar sabis na fiye da 4 hours;

1. Lokacin bugu da manna solder, ana bada shawarar yin amfani da manna mai siyar tare da abun ciki na ƙarfe na 85% zuwa 92% da rayuwar sabis na fiye da 4 hours;

2. Saurin bugawa Lokacin bugawa, saurin tafiye-tafiye na squeegee akan samfurin bugu yana da matukar mahimmanci, saboda manna mai siyar yana buƙatar lokaci don mirgina da kwarara cikin rami mai mutu.Tasirin yana da kyau lokacin da manna mai siyar ya yi birgima a ko'ina akan stencil.

3. Matsi na bugu Dole ne a daidaita matsin bugu tare da taurin magudanar ruwa.Idan matsi ya yi ƙasa da ƙasa, squeegee ɗin ba zai tsaftace manna solder akan samfuri ba.Idan matsa lamba ya yi girma sosai ko kuma ƙwanƙolin ya yi laushi sosai, matsewar za ta nutse zuwa samfurin.Fitar da manna solder daga babban rami.Ƙa'idar ƙira don matsa lamba: Yi amfani da gogewa akan samfurin ƙarfe.Domin samun madaidaicin matsa lamba, fara da yin amfani da 1 kg na matsa lamba ga kowane 50 mm na tsawon tsayin scraper.Misali, scraper 300 mm yana amfani da matsi na kilogiram 6 don rage matsa lamba a hankali.Har sai manna solder ya fara zama akan samfuri kuma ba a goge shi da tsafta ba, sannan a hankali ƙara matsa lamba har sai an goge man siyar.A wannan lokacin, matsa lamba shine mafi kyau duka.

4. Tsarin tsarin sarrafawa da ka'idojin tsari Don samun sakamako mai kyau na bugu, wajibi ne a sami kayan daɗaɗɗen solder daidai (danko, abun ciki na ƙarfe, matsakaicin girman foda da mafi ƙasƙanci mai yuwuwar motsi), kayan aiki daidai (na'urar bugu, samfuri). da Haɗuwa da scraper) da tsari daidai (matsayi mai kyau, tsaftacewa da gogewa).A cewar daban-daban kayayyakin, saita daidai bugu tsari sigogi a cikin bugu shirin, kamar aiki zafin jiki, aiki matsa lamba, squeegee gudun, demoulding gudun, atomatik samfur tsaftacewa sake zagayowar, da dai sauransu A lokaci guda, shi wajibi ne don tsara wani m tsari. tsarin gudanarwa da ka'idojin tsari.

① Yi amfani da manna mai siyarwa a cikin lokacin inganci daidai da ƙayyadaddun alamar.Ya kamata a adana manna mai siyar a cikin firiji a ranakun mako.Ya kamata a sanya shi a cikin zafin jiki fiye da sa'o'i 4 kafin amfani, sa'an nan kuma za'a iya buɗe murfin don amfani.Ya kamata a rufe manna mai siyar da aka yi amfani da shi kuma a adana shi daban.Ko ingancin ya cancanta.

② Kafin samarwa, ma'aikaci yana amfani da wuka mai motsawa ta bakin karfe na musamman don motsa manna mai siyar don daidaita shi.

③ Bayan nazarin bugu na farko ko daidaita kayan aiki a kan aiki, za a yi amfani da ma'aunin kauri na solder manna don auna kauri na bugu na manna.Ana zaɓar wuraren gwajin a maki 5 akan farfajiyar gwajin da aka buga, gami da na sama da ƙasa, hagu da dama da maki na tsakiya, da yin rikodin ƙimar.The kauri na solder manna jeri daga -10% to +15% na samfur kauri.

④ A lokacin aikin samarwa, 100% dubawa ana yin shi akan ingancin bugu na manna solder.Babban abun ciki shine ko tsarin manna mai siyar ya cika, ko kauri iri ɗaya ne, da kuma ko akwai tipping ɗin manna.

⑤ Tsaftace samfurin bisa ga buƙatun tsari bayan an gama aikin kan aiki.

⑥ Bayan gwajin bugu ko gazawar bugu, manna mai siyarwar a kan allon buga ya kamata a tsabtace shi sosai tare da kayan aikin tsaftacewa na ultrasonic da bushewa, ko kuma tsabtace shi da barasa da iskar gas mai ƙarfi don hana ƙwayar solder a kan jirgin daga lalacewa lokacin da yake. amfani kuma.Solder bukukuwa da sauran al'amura bayan reflow soldering

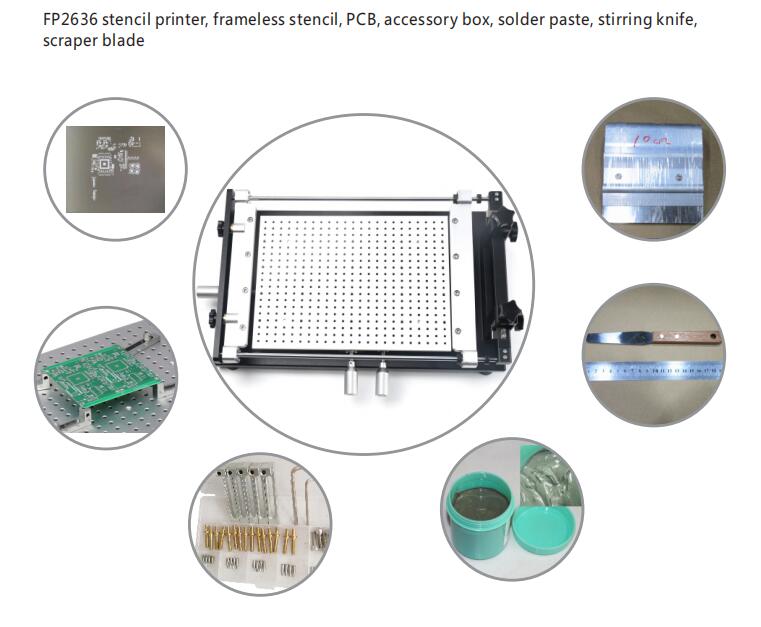

NeoDen yana ba da cikakkiyar mafita na layin taro na SMT, gami da tanda na sake kwarara SMT, injin siyar da igiyar ruwa, na'ura mai ɗaukar hoto da wuri, firintar manna mai siyarwa, mai ɗaukar PCB, mai saukar da PCB, mai ɗaukar guntu, injin SMT AOI, injin SMT SPI, injin SMT X-Ray, SMT taron layin kayan aiki, PCB samar da kayan SMT kayayyakin gyara, da dai sauransu kowane irin SMT inji za ka iya bukatar, da fatan za a tuntube mu don ƙarin bayani:

Hangzhou NeoDen Technology Co., Ltd

Yanar Gizo1: www.smtneoden.com

Yanar Gizo2: www.neodensmt.com

Lokacin aikawa: Yuli-21-2020