Matsakaicin Lalacewar taron PCB Ta Amfani da Inspection Na gani Na atomatik (AOI)

Matsakaicin Lalacewar taron PCB Ta Amfani da Inspection Na gani Na atomatik (AOI)

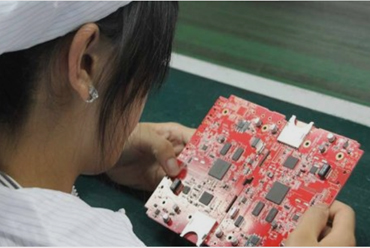

Inspection Optical Inspection (AOI), wanda shine dubawar gani mai sarrafa kansa na Hukumar da'ira ta Buga (PCB), tana ba da 100% abin da ake iya gani da binciken haɗin gwiwa.An yi amfani da wannan hanyar gwaji a masana'antar PCB kusan shekaru ashirin.Yana taka muhimmiyar rawa wajen tabbatar da cewa babu kura-kurai a cikin taron.Dabarar, wacce ke amfani da hasken wuta, kyamarori, da kwamfutocin hangen nesa, an haɗa su a cikin tsarin haɗin gwiwa don tabbatar da mafi girman ingancin da zai yiwu a cikin kowane lokaci na rayuwar samfurin.Hanyar yana ba da damar dubawa mai sauri da daidai kuma ana iya amfani dashi a matakai daban-daban na tsarin masana'antu.Don haka, menene duk abin da kayan aikin Inspection Optical (AOI) zai iya bincika a cikin waniPCB taro?

Gano Lalacewar Amfani da AOI

Da zarar an gano kuskuren, da sauƙi zai kasance don yin samfurin ƙarshe don dacewa da bukatun ƙira ba tare da wani lahani ba.Ana iya amfani da wannan sanannen sanannen fasaha da aka yarda da ita don bincika waɗannan abubuwan a cikin taron PCB:

- Nodules, scratches da stains

- Bude da'irori, guntun wando da kuma bakin ciki na solder

- Ba daidai ba, ɓacewa da karkatattun abubuwan da aka gyara

- Rashin isasshen wurin manna, shafa, da gadajewa

- Rasa ko kashe kwakwalwan kwamfuta, skewed kwakwalwan kwamfuta da lahani-daidaitacce

- Solder gadoji, da kuma ɗaga kai

- Laifin faɗin layi

- Cin zarafin tazara

- Wuce tagulla, da kushin da ya ɓace

- Gajerun wando, yanke, tsalle

- Lalacewar yanki

- Matsalolin abubuwan da aka gyara, polarity bangaren,

- Kasancewar bangaren ko rashi, skew bangaren daga faifan dutsen saman

- Wuce kima mai saida gidajen abinci da rashin isassun kayan haɗin gwiwa

- Juya abubuwan da aka gyara

- Manna a kusa da jagora, gadoji mai siyarwa, da rajistar manna mai siyarwa

Tare da gano waɗannan kurakurai a matakin farko, masana'anta na iya samar da allon zuwa matakan da ake buƙata.Don ba da gudummawa ga hanyoyin gwaji, akwai kayan aiki da yawa da ake samu tare da ci-gaba mai haske, na'urorin gani, da damar sarrafa hoto don keɓancewar keɓantacce.Waɗannan injunan suna ba da sauƙi, fasaha da aiki mai ƙarfi, wanda ke haifar da rage farashin sake aikin ku da haɓaka tsarin gwaji.AOI kasancewar hanyar gwaji mai mahimmanci wanda ke ƙayyade ingancin hukumar gabaɗaya, yana da mahimmanci don cin gajiyar sabis ɗin daga manyan kamfanoni.Koyaushe kyakkyawan zaɓi ne don haɗin gwiwa tare da masana'antun PCB waɗanda ke ba da gwajin AOI hannu-da-hannu.Wannan yana taimaka wa masana'anta don gwada allon a kowane mataki na taron ba tare da bata lokaci ba.

Lokacin aikawa: Juni-15-2020